Why is the price of five-axis machining center so high?

Release time:2024-05-29

Why is the price of five-axis machining center so high?

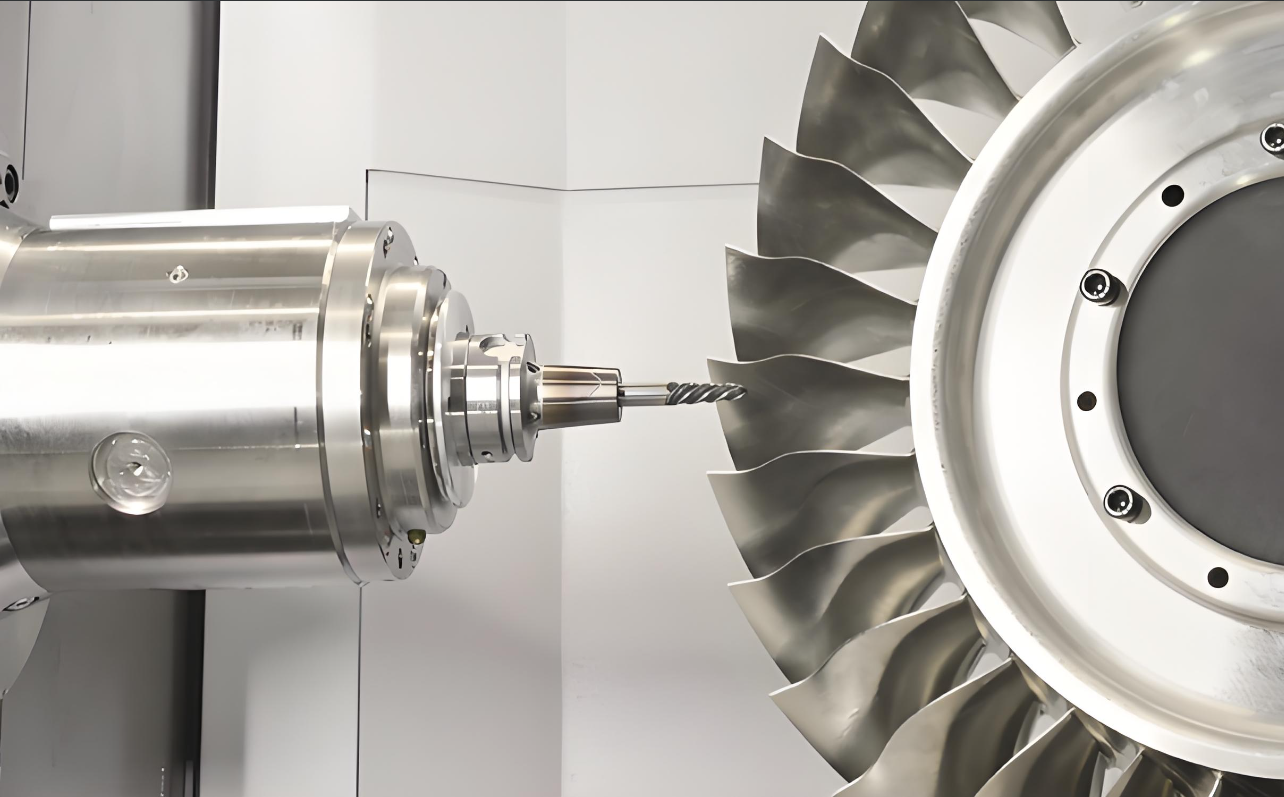

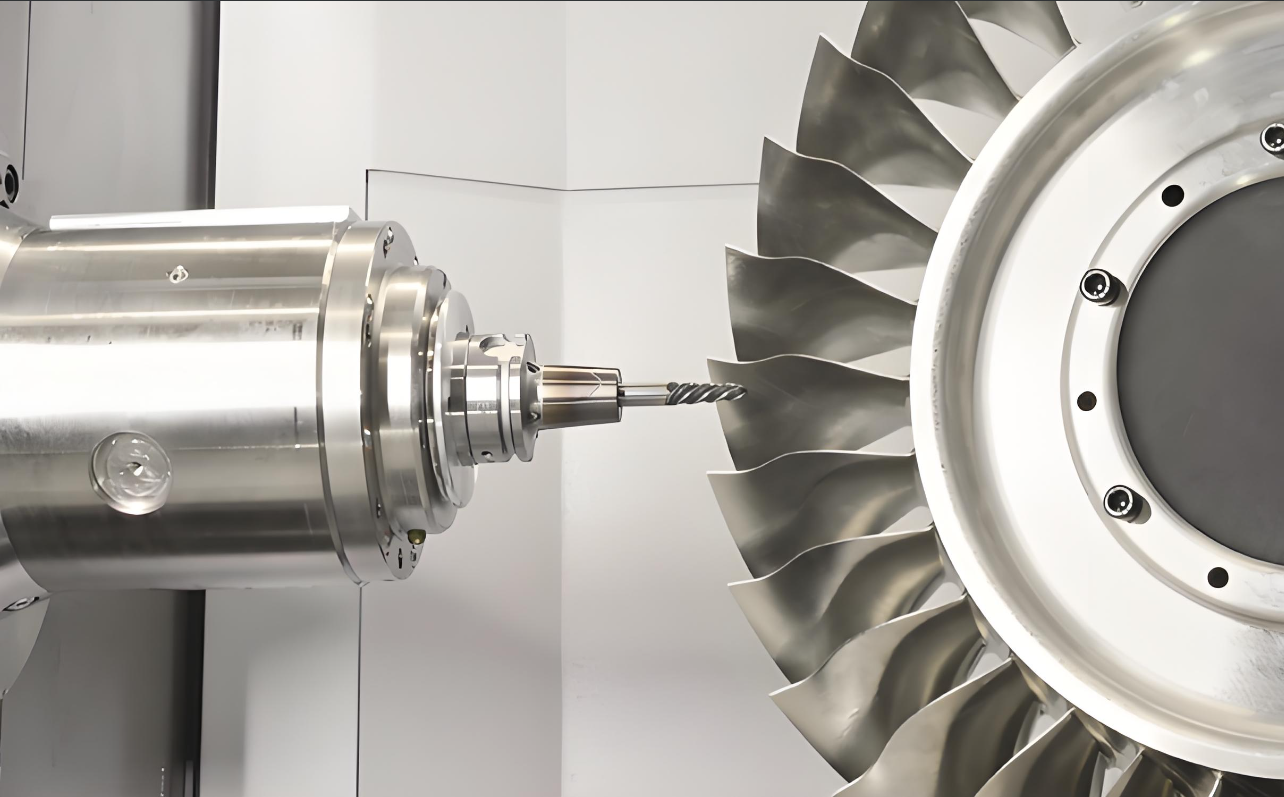

Five-axis machining center is a mode of CNC machine tool processing, is currently an important equipment in precision parts processing, but the price of the equipment is higher than ordinary processing equipment, so we know what is the reason for the high price of the equipment?

First, high processing precision.

The machining accuracy of the five-axis linkage machining center is generally up to 0.001 ~ 0.1mm, and the five-axis linkage machining center is controlled in the form of digital signals. For each pulse signal output by the CNC device, the moving parts of the machine tool move a pulse equivalent (generally 0.001 ~ 0.1 mm). In addition, the average error between the reverse clearance and pitch of the machine feed transmission chain can be compensated by a numerical control device. Therefore, the positioning accuracy of the five-axis machining center is relatively high.

Second, the processing quality is stable and reliable.

With a batch, machining parts on the same machine tool, under the same processing conditions, using the same tool and processing program, the tool trajectory is exactly the same, the parts are consistent and the quality is stable.

Third, high productivity.

The five-axis linkage machining center can effectively reduce the processing time and auxiliary time of parts. The wide range of spindle speed and feed speed allows the machine to perform strong cutting with large cutting amounts. The fast motion positioning and high-speed cutting of the moving parts of the five-axis machining center can reduce the turnover time between the processes of semi-finished products and improve production efficiency.

Fourth, highly flexible.

Machining parts in a five-axis machining center mainly depends on the machining program. It is different from ordinary machine tools, there is no need to manufacture and replace many tools and fixtures, and there is no need to adjust the machine frequently. Therefore, it is suitable for frequent replacement of parts. It is suitable for single piece, small batch production and new product development, shortens the production preparation cycle, and saves the cost of a lot of process equipment.

Five, save effort.

After the five-axis linkage machining center is adjusted before processing, input and start the program, the machine tool can automatically continue processing until the processing is completed, the operator is the five-axis linkage machining center, also known as the five-axis linkage machining center, which is specially used for machining complex surfaces. It has the advantages of high processing accuracy and high efficiency, and can complete complex processing by clamping the workpiece at one time, and can process a variety of products and parts of the same type from multiple angles. Five-axis linkage machining centers have also become buyers of complex workpieces such as auto parts, large crankshafts, and heavy-duty generator rotors.

There are also reasons for the high price of the five-axis machining center, mainly because it has the advantages of high processing precision, stable and reliable processing quality, high productivity, high flexibility, labor-saving and time-saving, and it is precisely because it has these advantages, better processing performance, and is very popular in the market.