What are the important factors to reduce the cost of zinc alloy die casting?

Release time:2024-05-10

What are the important factors to reduce the cost of zinc alloy die casting?

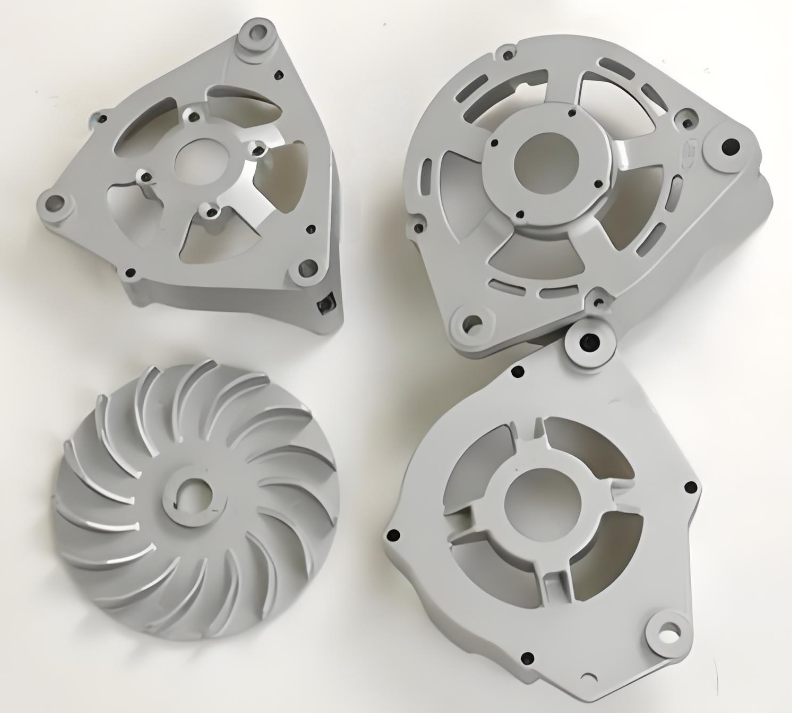

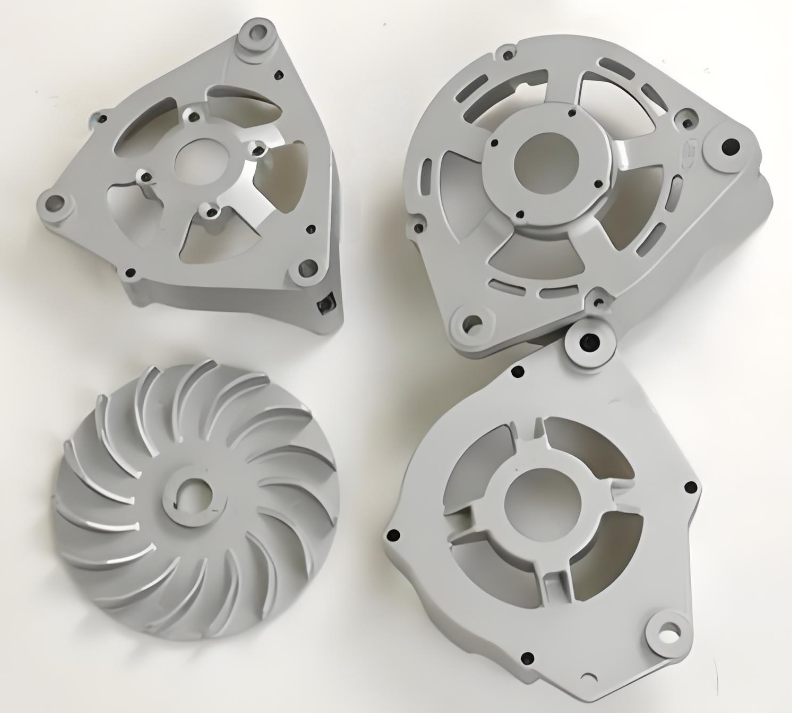

The increase in demand for zinc alloy die casting has further promoted the expansion of the export zinc alloy die casting market, more and more domestic die casting plants began to export zinc alloy die casting, die-casting parts of good surface quality, high dimensional accuracy, low waste rate, wide range of application, low technical level of workers, greatly reducing the labor intensity of workers, improve the working environment. However, the disadvantage is that the cost of die casting is relatively high. In order to reduce the cost of die casting, various die casting factories are exploring ways to reduce costs.

In order to reduce the cost of zinc alloy die casting, you can consider from the equipment, raw materials, die casting process and other aspects.

1. When choosing the right die casting machine, not only the actual situation of the die casting plant should be considered, but also the equipment with the right price should be selected, and the operating cost of the equipment should be considered. The following items should be considered:

1. We must pay attention to the choice of dust removal equipment. When choosing production equipment, most die casting factories tend to pay more attention to the quality of the equipment, while ignoring the quality of the dust removal equipment. In fact, the quality of dust removal equipment directly affects the quality and cost of zinc alloy die casting. If the dust removal effect of the dust removal equipment is not good, it will not only affect the working environment, pollute the air, but also affect the impurity content of zinc alloy. The direct result is to increase the production cost of zinc alloy die casting, which is not desired.

2. The reliability of the equipment and its maintenance cost must be considered. The processing method, assembly level and equipment configuration level of the equipment manufacturer determine the reliability of its production equipment. If the reliability of the device is poor, the possibility of device failure Increases the number of device components, which reduces the utilization of the device. This will not only increase the workload of maintenance personnel, increase the maintenance cost of equipment, but also reduce production efficiency and increase production costs.

3, under the premise of considering the energy consumption of the equipment, meet the requirements of the die casting process, minimize the installed capacity, avoid the phenomenon of big carriages, make full use of internal resources, reduce unnecessary energy waste, achieve the full use of equipment, maximize the use of energy, and improve the efficiency and social benefits of the die casting plant.

Secondly, correct and reasonable die casting process is the key to reduce the cost of zinc alloy die casting. Is the production process reasonable? It directly affects the production of castings, quality of castings and cost of castings. When developing the production process, the following points should be mainly determined:

Determine the appropriate die casting process parameters

(1) In production, two trends must be overcome: on the one hand, blindly increase the strength to ensure quality, so that the casting cost increases, resulting in waste; On the other hand, the strength is reduced to ensure the cost, which leads to poor quality. The stable and wide fluctuation range makes the quality of zinc alloy die casting greatly affected by raw materials and operators. The die casting plant should determine the appropriate final strength according to its own situation, so as to save raw materials and reduce the die casting cost to a large extent under the premise of ensuring the quality of zinc alloy die casting.

(2) Determine the appropriate die casting process, the yield directly affects the cost of zinc alloy die casting, the appropriate die casting process can not only ensure the quality of zinc alloy die casting, but also reduce the cost of die casting casting, reducing the casting scrap rate is one of the most obvious and direct measures.

3. The correct selection of raw materials is the basis for reducing the cost of zinc alloy die casting. The choice of raw materials has a greater impact on the cost of die casting, which has been recognized by most peers, because the quality of raw materials on the one hand affects the addition and consumption of various materials, and on the other hand affects the quality of castings. Other. Quality indicators. A suitable and reliable zinc material manufacturer must be selected to ensure the quality and stability of the raw materials in the die casting plant.