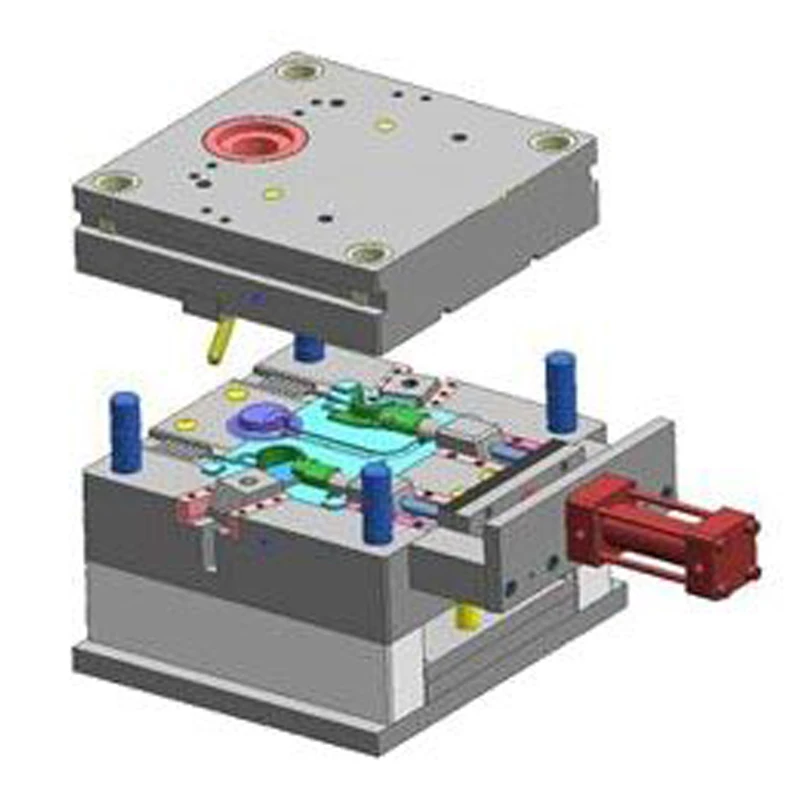

Quality control Mould Quality process: Receive design data - Fix quality control point - Mould raw material check (Dimensional check + metallographic analysis) - Production process check (outgoing parts + component) - Assembly check - Trial moulding part check - Final check Production quality check: Spot check on production line + Final check

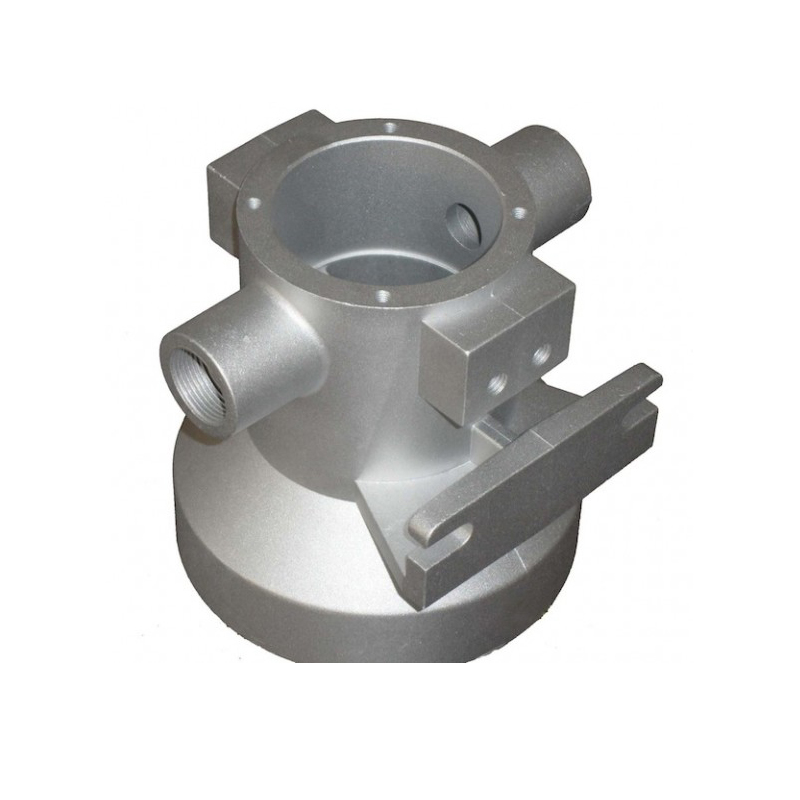

High Pressure Magnesium A356 Aluminum Metal Die Casting Mold Parts

Product Specifications:

| Product Type | High Pressure Magnesium A356 Aluminum Metal Die Casting Mold Parts |

| What We Offer | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Standard | DIN GB ISO JIS BA ANSI |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Packing | Foam, Carton, Wooden boxes, or as per the customer’s requirements |

| Payment Terms | T/T,Western Union,Paypal |

Our Advantages:

| Extremely strong and light weight | Nice looking with competitive |

| Corrosion resistance | Abrasion- resistance |

| Low coefficient thermal expansion | Impact resistance |

| durable and long-lasting | Environmentally safe |

| Non-magnetic electromagnetic | Wide temperature range use |

| Ease of fabrication & installation | Excellent fatigue resistance |

| Without residual glue after remove | Convenient to construct |

| Good resilience | Convenient to pack and transport |

| Tensile strength | UV resistance |

Products show