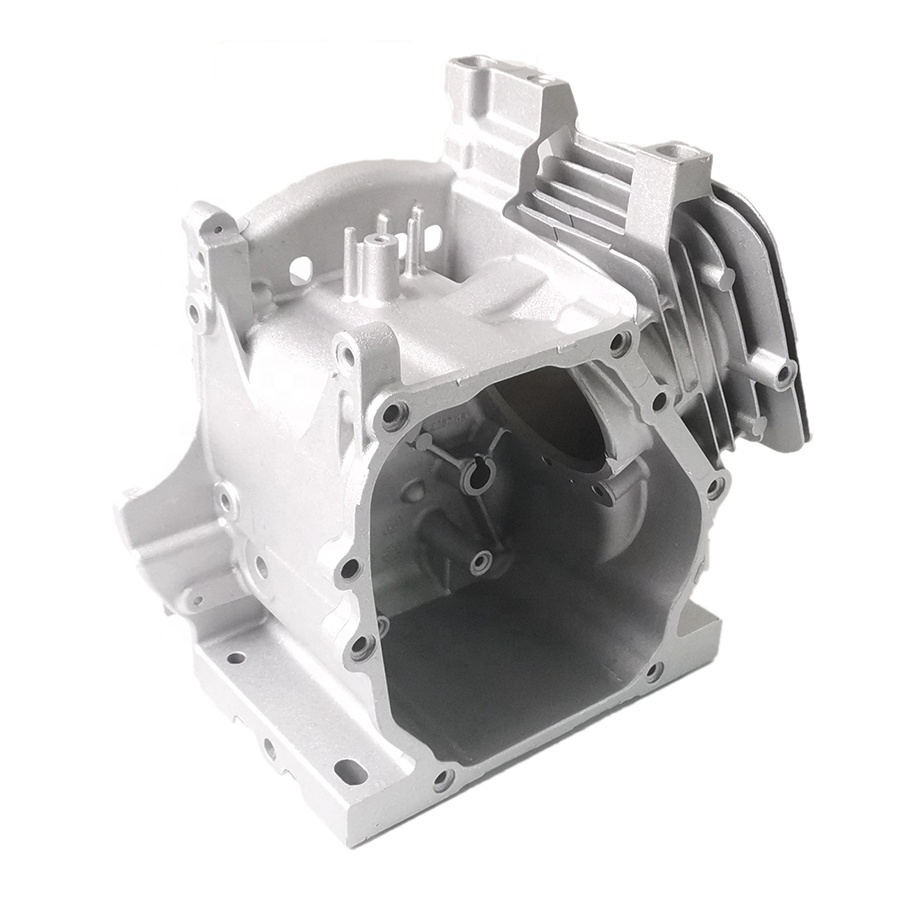

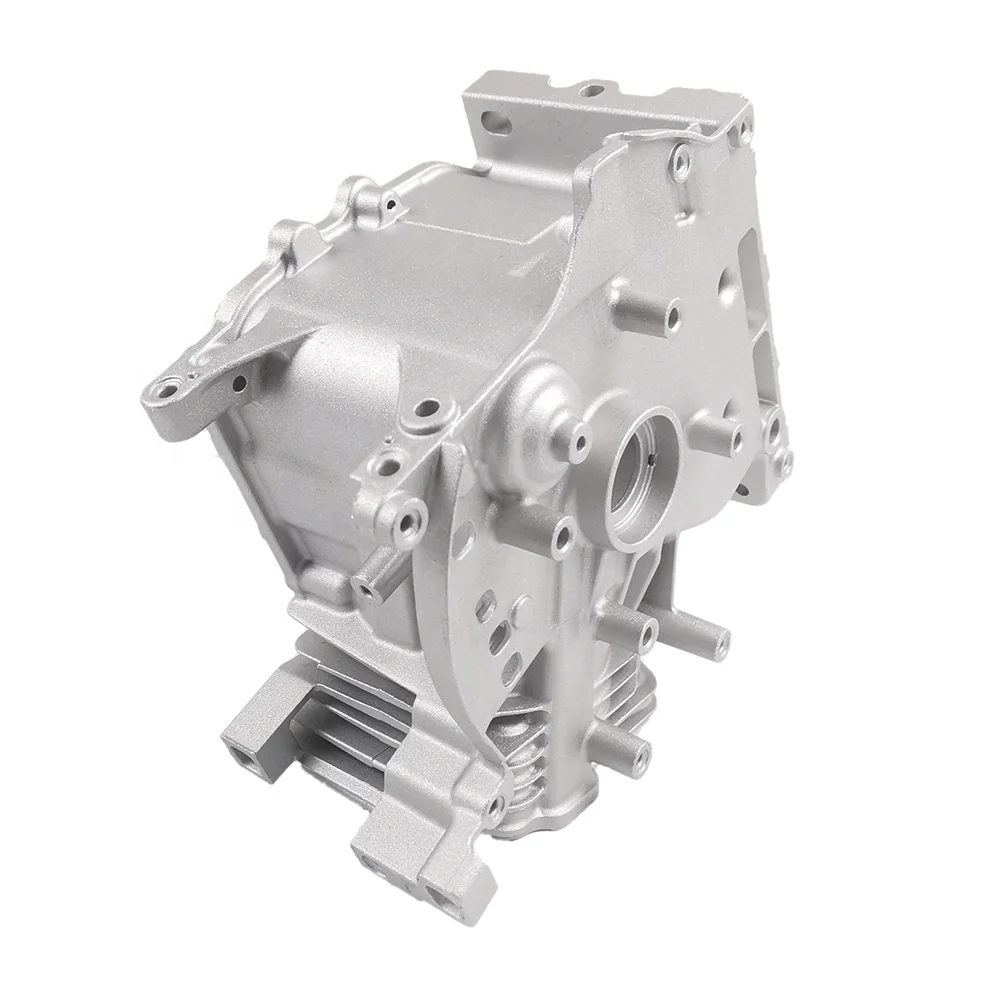

Product Description Professional Customized Die Casting Parts for Auto And motorcycle Professional Customized Die Casting Parts for Auto And motorcycle ALUMINUM DIE CASTING Product description Aluminum die casting mold, Aluminum die casting parts Mat

Professional Customized Die Casting Parts for Auto And motorcycle

|

ALUMINUM DIE CASTING |

|

|

Product description |

Aluminum die casting mold, Aluminum die casting parts |

|

Material |

Aluminium die-casting and low-pressure die-casting: A360,ADC12,A380,ZL101,102,114,etc |

|

Applicatin |

All kinds of cars auto parts, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switcher, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more. |

|

Service |

CNC Machining, Turning and Milling, Laser Cutting, Stamping, Die Casting, OEM Parts |

|

Casting tolerance |

+/-0.01mm ~ +/-0.05mm |

|

Casting roughness |

Ra1.6-3.2 |

|

Casting weight range |

0.005-50kg |

|

Surface Treatment |

Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Dacromet, Enamel Coating etc. |

|

Quality Assurance |

High Precision and Quality Casting and Aluminium Die Casting Parts, 100% inspection |

|

Industries Served |

Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical, Marine, Machinery, Furniture, Food, Lighting, Telecommunication, etc |

|

File Formats |

Solidworks, Pro/Engineer, Auto CAD, PDF, JPG, DXF, IGS, STEP |

|

Equipment |

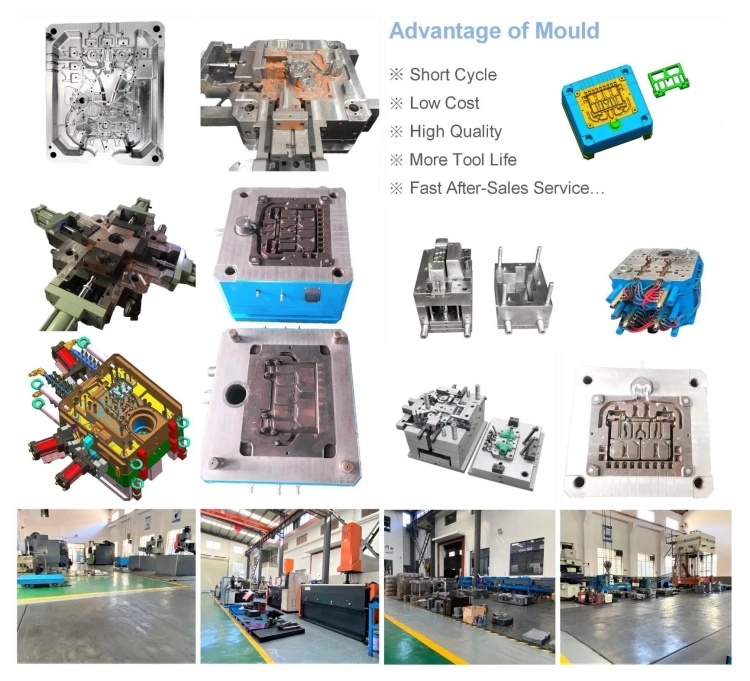

Die casting machines from 58T to 800T, CNC centers, CNC milling machines, Electropulsing machines, Wire cutting machines, Mold punchining machines, Drilling tapping machines, Sandblasting machines, Vibration machine, Lathe machines etc. |

|

OEM and ODM |

Acceptable |

Product Feature

aluminium die casting, aluminium die casting parts, die casting mould, zinc die casting, aluminum die casting manufacturer

Advantage of Aluminum Die casting

High-speed production – Die casting provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical castings can be produced before additional tooling is required.

Dimensional accuracy and stability – Die casting produces parts that are durable and dimensionally stable, while maintaining close tolerances. They are also heat resistant.

Strength and weight – Die cast parts are stronger than plastic injection moldings having the same dimensions. Thin wall castings are stronger and lighter than those possible with other casting methods. Plus, because die castings do not consist of separate parts welded or fastened together, the strength is that of the alloy rather than the joining process.

Multiple finishing techniques – Die cast parts can be produced with smooth or textured surfaces, and they are easily plated or finished with a minimum of surface preparation.

Simplified Assembly – Die castings provide integral fastening elements, such as bosses and studs. Holes can be cored and made to tap drill sizes, or external threads can be cast.

aluminium die casting, aluminium die casting parts, die casting mould, zinc die casting, aluminum die casting manufacturer

aluminium die casting, aluminium die casting parts, die casting mould, zinc die casting, aluminum die casting manufacturer

Product Application