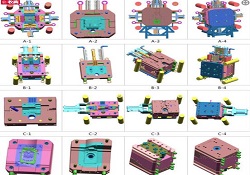

首先,这是一个很好的问题。 在我们开始自己捏造之前排除,让我们继续前进,找出什么 塑料注塑成型和模具铸造是第一位的。 这些是模具之间的差异。

什么是压铸模具?开发制造过程与材料的选用:

压铸是一种自动铸造工艺,其中将液态熔体在高温下压入模具中压力(150至1200 bar)和 高填充速度(最高540 km / h)。

压铸是最经济,最快的成型工艺之一。 这种生产过程的优点是成千上万仅使用一个模具就可 以相对快速地生产铸件。 所生产的所有组件均具有统一的质量,并且单位成本较低。 但是制造过程看起来如何? 可以使用什么材料?在哪些区域使用铸件?

如何定义压铸模具

压铸是一种自动铸造工艺,其中将液态熔体在高压(150至1200 bar)和高填充速度下压入模具中(最高540 km / h)。 通常使用低熔点的合金。 此铸造工艺特别适合于组件的批量生产因为不同于砂型铸造,例如使用永久金属模具,铸造后不必将其销毁。 有可能产生大壁厚低的复杂组件。

[开启/关闭]

It is considered to be one of the most popular manufacturing processes today. It is widely used by custom belt buckle manufacturers. Depending on what is needed, raw materials can be made of metal, glass, confections, or elastomers. But the most popular raw material is plastic.

How Are Products Made with Injection Molding?

First, design and plans must be finalized. After everything is ready, raw material like duraflex material will be melted in a big barrel. After melting, it is injected into a mold that is usually made of strong metal. After taking the shape of the mold, it is allowed to cool and ejected from the machine. These are the injection moulding process parameters.

Some products manufactured under this method are automotive parts, toys, kitchen utensils, combs, bottles, appliances, educational supplies, strap buckles, and a whole lot more.

The Injection Moulding Advantages

This manufacturing process has a lot of advantages. First, it is very cost effective because little or no waste is produced. Second, it is very eco-friendly due to the first reason. And third, it produces high quality products. With all of this in mind, can you even imagine a life without injection molded plastic?

What is Die Casting?

Now that you are already familiar with injection molding, it will be easy for you to understand what die casting is. Unlike injection molding, die casting only engineers various metal parts or products made of metal.

How Are Products Made with Die Casting?

The process is also similar to injection molding. Raw materials made of metal is melted under extreme but exact temperature, forced into durable steel molds and allowed to cool before taken off the machines.

Are you a toy car collector? Your toys probably are made through the die cast system. Steel pipes, car parts, electronics, golf equipment, and faucets are just some of the products made through it as well.

The Die Casting Advantages

It has numerous advantages. First, the system can be done in an automatic fashion. Second, the molds can be used over and over again due to its durability. Third, the products made through this are more durable and has a longer service life. And fourth, it is economical too!

So Which is Better?

There may be a difference between mould and pattern in casting but the answer totally depends on what you need. If you need products that are very durable and can withstand extreme temperature and has magnificent electrical properties, die casting should be your choice but if you need plastic products with highly complex designs but are durable for everyday life, then injection molding maybe it.

You may also consider the types of moulding available for each system before you can finally choose the right one for you.